FoulingCure

Saving time and energy

FoulingCure

FoulingCure is required for Particulate fouling.

FoulingCure increases the flow rate by 300-400% over 1-3 plate channels at a time and increasing the self-cleaning effect by 900-1600%.

Preventing particles from depositing on the plates and deteriorating the heat transfer.

Cleaning sequence is performed while the plate heat exchanger is in full operation and no energyloss or downtime – Cycle is every hour up to daily basis.

The FoulingCure-flow is provided by an external pump and the FoulingCure rinsing head is guided by a hydraulic cylinder.

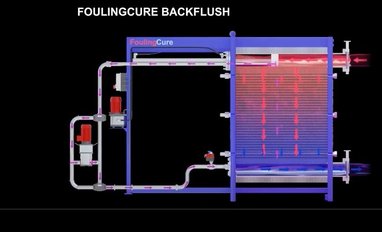

FoulingCure with BackFlush

FoulingCure with BackFlush

FoulingCure with Backflush is required when larger particles or fibers are likely to block the inlet of the plate channels. Instead of pressing large particles into the plate channels, the system reverses the flow direction and removes the particles or fibers.

In the first pass, FoulingCure backflushes as the rinsing head moves forward. In the second pass, the rinsing head moves backwards and switches to the normal flow for flushing.

The Backflush modus is obtained by installing two extra valves along with the standard FoulingCure system.

FoulingCure with Back Flush and CIP

FoulingCure with Backflush in combination with CIP (Cleaning in Place) generates flow to flush away dissolved material and larger particles.

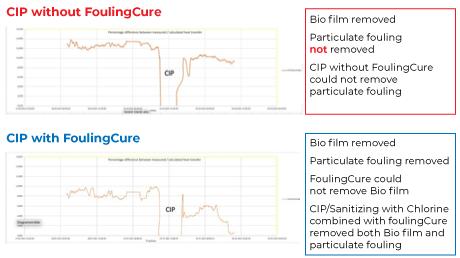

FoulingCure with CIP

FoulingCure with CIP is required when having Biological & Chemical fouling or Precipitation - scale formation due to dissolved substances.

Using a traditional stand-alone CIP for cleaning a plate heat exchanger do is not always fully restore the performance. Dissolving solids or killed bacteria leaves a mix of dissolved solids and particles on the plates.

FoulingCure in combination with CIP generates sufficient flow to flush away dissolved material and particles for getting the plate heat exchanger back to 100% performance.

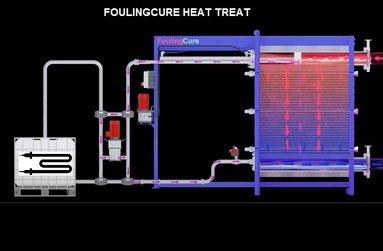

FoulingCure with HeatTreat

FoulingCure with HeatTreat prevents organisms from growing on the plate heat exchanger plates for low temperature applications. – Especially in open loop water systems. FoulingCure with HeatTreat will kill and flush off the larvae before they start growing on the plates.

FoulingCure with HeatTreat is also an effective solution where sewage water applications and large heat pumps are involved. In such applications, fat solidify on the plates. FoulingCure with HeatTreat will melt or dissolve and flush off fat and particles.

FoulingCure Heat Treat with CIP can make chemical CIP more effective.

FoulingCure with

BackFlush - CIP - HeatTreat

We keep them all Clean!